Tippers are under construction, coming soon.

Tippers

Tippers are under construction, coming soon.

Our ladle refining products are engineered for clean steelmaking practices in high-productivity steel shops. These custom designed additives quickly generate a fluid ladle slag to improve shop productivity and final product quality.

We can rapidly provide products of most grades and sizes, so do not hesitate to contact our sales office or representative.

Titanium is a high strength low density metal, with high corrosion resistance. Titanium can be welded, machined and formed the same as any other steel.

Titanium has a melting point temperature of 1668°c which is greater than steel yet titanium weighs almost half that of stainless steel. Due to its unprecedented strength and non-corrosive characteristics, titanium is the metal of choice for engineers in the aerospace, petrochemical and medical industry.

Titanium is used in Aircraft for the engines and frames, Primairy steel, Automotive, Petrochemical, Medical implants, Offshore piping systems, Desalination plants, Pulp and Paper plants and Heat Exchangers (tube and compact types) and many more!

Commercially pure Grades 1-4 are most commonly used for their high corrosion resistance. Grade 5 (Titanium with 6% Aluminium and 4% Vanadium) is used for its high strength.

If you have any questions or concerns about using or handling titanium we are happy to provide onsite support!

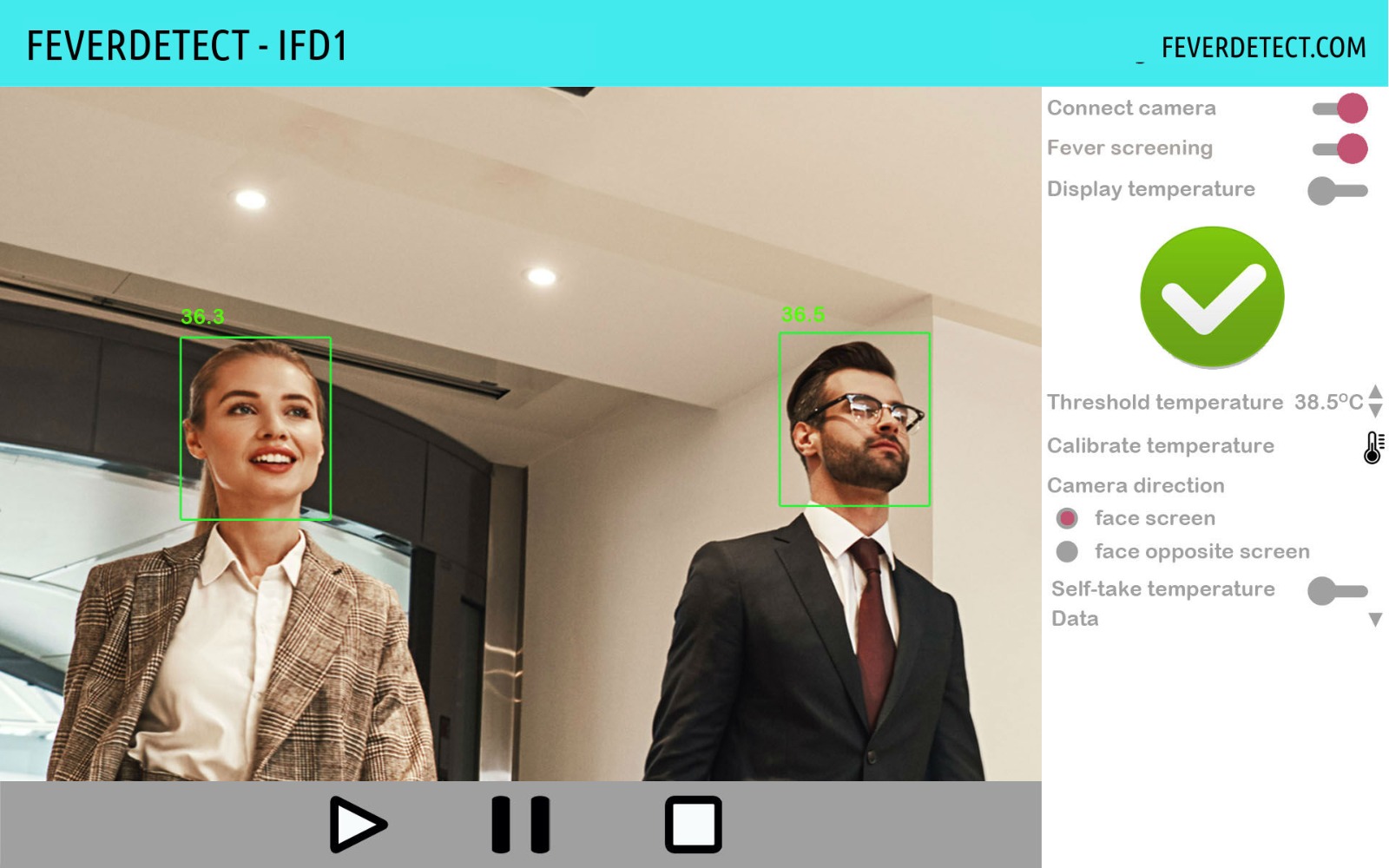

Heavyduty Industries™ is the official developer and distributer of the Feverdetect™. Feverdetect™ is integrated with smart camera fever detection technology that helps to detect elevated skin-surface temperatures which may indicate the presence of fever, a symptom of, for example, the Covid-19 virus.

Our clients use our solutions as an adjunctive diagnostic tool, to detect people with a potential fever to contain and limit the spread viruses. Our fever detection solutions are a vital tool in the detection of elevated body temperatures in high-risk groups such as miners, metal factory workers travelers and office workers in all industries.

This industrial developed solution can be used for rapid and preliminary fever detection in office buildings, factories, stations, supermarkets, airports and other public places.

The software will use AI to detect faces. Upon detecting of human face, it will put a bounding box around the face. The software will extract the thermal temperatures of the area from the thermal camera and take the maximum value as a measured temperature. It will compare this measured temperature against the threshold temperature and display the result above the bounding box of the face.

The FeverdetectOne Integrated Fever detection (IFD) solution uses a modern tablet PC, the innovative Feverdetect sensitive thermal camera, and the Feverdetect fever detection management software.

Heavy Duty Industries assures the right industrial mounting solution to protect the system in public places. We create the turn key safety solution for your employees, visitors and customers!

Safety for everyone everywhere!

The cast products manufactured in our production facilities we can produce castings which have a delivery weight from 1 to 4500 kg per piece. However, in cooperation with our partners, we can produce castings up to a delivery weight of several tons per piece.

The model equipment is produced in cooperation with our experienced contractual partners.

For simple castings, the patterns are produced both by hand and on conventional processing machines. Geometrically more demanding ones, on the other hand, are produced on CNC-controlled milling and turning machines.

With the solidification simulation we can offer our customers computer-aided simulation of a casting process

This enables us to identify possible weak points in advance of the casting development.

The solidification simulation is a very useful and economical supplement to the unavoidable practical tests.

The quality of the raw material is also decisive for the final product.

All heat treatments are carried out in our own electrically heated deep furnaces. Our key competencies are:

With appropriate heat treatment, the required mechanical properties of castings can be ensured.

On state-of-the-art horizontal and vertical MAZAK CNC lathes with driven tools, the finishing of the castings is carried out in our company.

To ensure the high quality required by the customer, we carry out destructive and non-destructive testing procedures.

With Heavy Duty Industries™ your component castings are in One stop Shop!

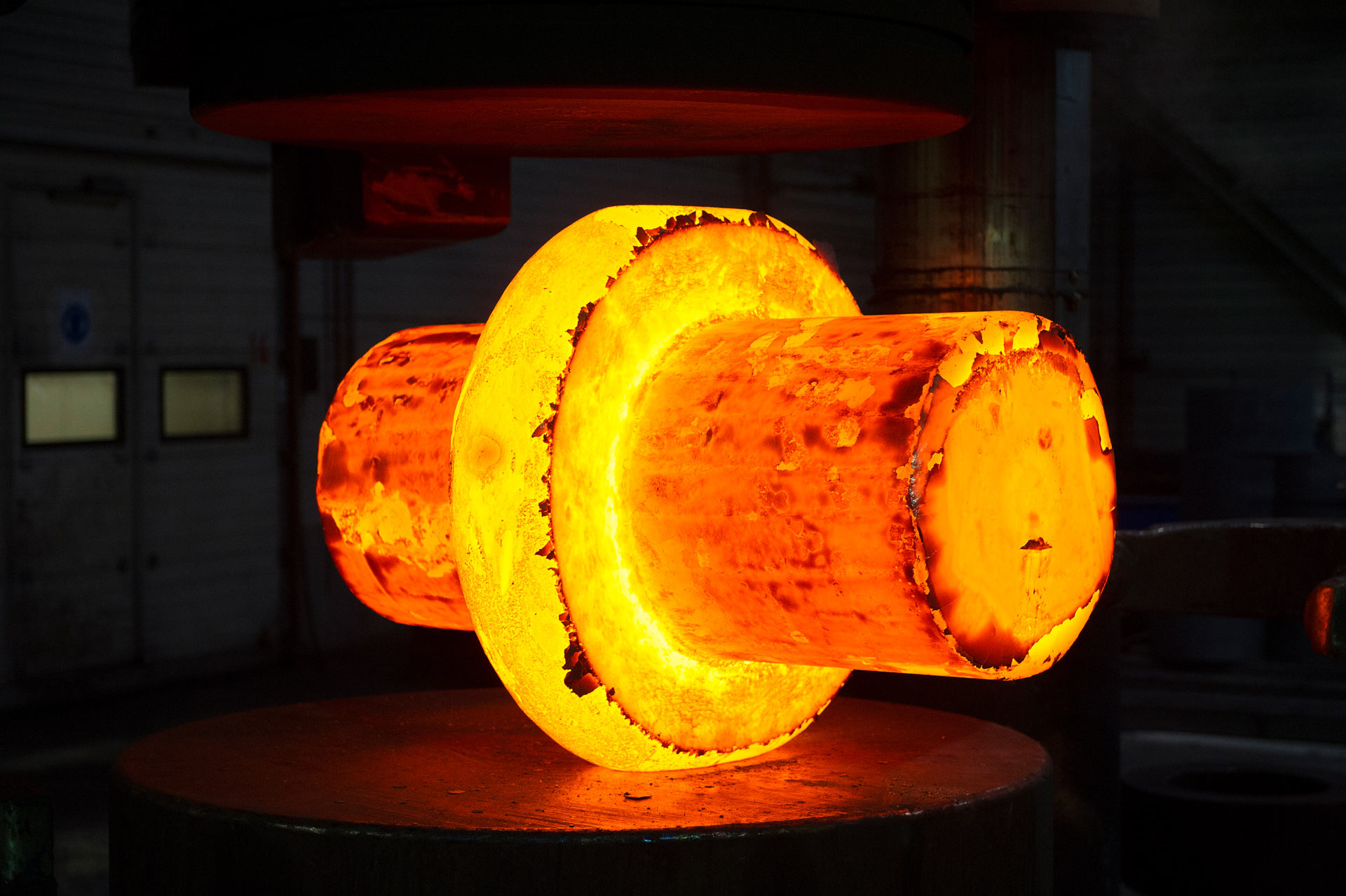

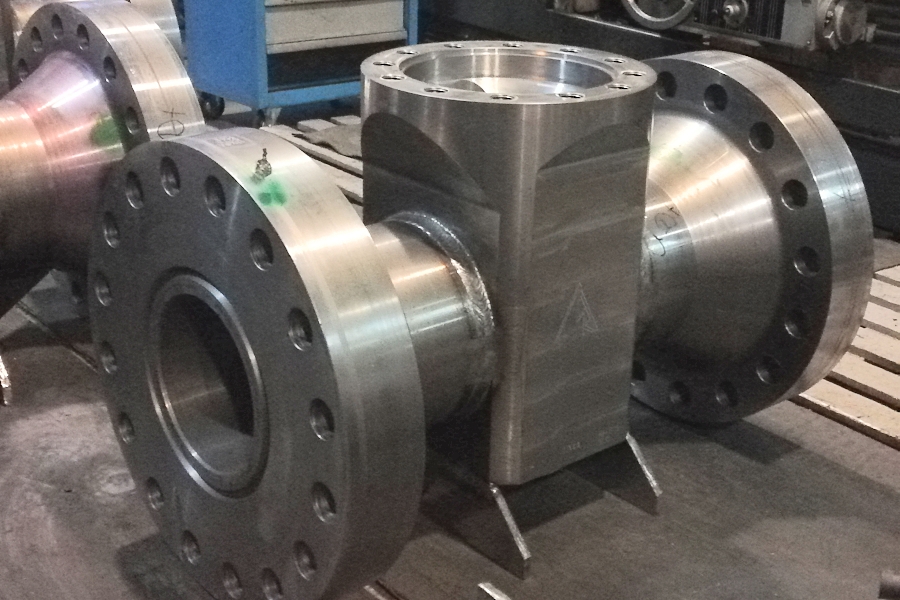

We are your partner when high mechanical stress has to be taken into account and the highest reliability under aggressive environmental or ambient conditions is required.

From steel production to the completion of the forged product, we carry out every step in the production process. We take responsibility ourselves and ensure that our customers receive consistent quality assurance. We check and document the quality of our products at every point of the production chain.

Our open-die forgings are characterised by the tightest tolerances and large dimensions. In our ultra-modern facilities, we manufacture forgings to drawing with a weight of up to 35 tons. We have many areas of expertise, including the production of impellers, shafts and discs, for compressors or turbines and components for fasteners, separators, pumps and valves in a pre-machined condition.

Precision and resilience, as required for drill teeth, shrouds or mandrels, for example, are the hallmarks of our drop forgings. The products that we develop together with our customers have proven themselves under the toughest operating conditions and enjoy an excellent reputation worldwide.

Heavy Duty Industries™ has over the years been supplying critical forged components for the Mining and Metal industry succesfully.

Heavy Duty Industries™ is an end-to-end partner for high-precision components specialized into the global, mining & metal producing industry.

Our in-house technologies and specialised services allow us to manage every step in your project, as well as the progression between them. We support every customer with a complete, individually tailored service from design and raw material up to the right logistical after service.

Heavy Duty Industries™ is the One stop shop for all mining wear parts!

Heavy Duty Industries™ has a close cooperation with the Dutch firm Hilco, where we offer exclusively outside the Netherlands a complete range of welding consumables and abrasives specifically to our customers within our primary industries.

Our greatest strength is the diversity of our line of products, which ranges from unalloyed to high-alloyed steel and aluminium alloys. Our welding consumables are tested, certified, and considered reliable by both our customers and internationally recognized classification institutes including Lloyds Register of Shipping, ABS, DNVGL, and TüV.

We are committed to enhancing relationships with our business partners, which effectively optimizes our mutual success in business.

28 September 2015 Hilco celebrated its 100th anniversary. Hilarius is designated as purveyor to the royal household by the appointment of the court of the Netherlands.

Learn more about our cooperation with Hilco by watching the corporate movie here.