Our know-how — your advantage

Heat treatment is inextricably linked to all the products we produce in every industry. We get the most out of your tool steel through our in-house developed heat treatment protocols.

Key values

- Quality

- Technical competence

- Process control

- Organized

- Flexibility

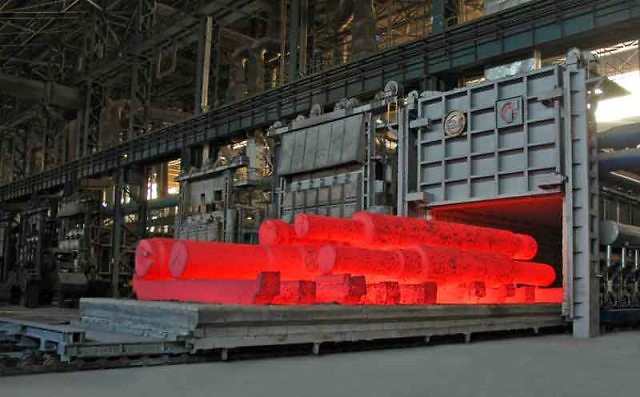

Competencies in heat treatment

- General, cold tough and heat resistant structural steels

- Q & T steels

- Steels for surface hardening

- Tool steels for cold and hot work

- Rust and acid-resistant steels etc.

We offer the following heat treatments

- Tempering (hardening and tempering)

- Soft annealing

- Solution heat treatment

- Stress relief annealing

- Normalizing

- Treatment to hardness range (+TH=formerly BF annealing)

- Treatment on ferrite-pearlite structure (+FP=formerly BG annealing)

Dimensions + weights

- Operating weight: from 10 kg to 15,000 kg

- Maximum temperature: 1080°C

- Maximum l/w/h: 6,700 x 1,700 x 1,240 mm or 5,540 x 2,650 x 1,560 mm

Quenching

The right medium for your material Basin size 80 m3

Isorapide 277 HM

Highly evaporation-resistant high-performance quenching oil with a very short main steam phase for low-distortion quenching of low- and high-alloy steels.

Ferroquench 2000I

Polymeric water-miscible non-flammable quenching medium, application concentration of approx. 9%. The quenching effect with this application concentration is slightly higher than with a high performance quenching oil for quenching low and unalloyed steels.

Ferroquench HQ-RS

Polymeric water-miscible quenching medium with a concentration of 6%. For shortening the main steam phase of the water and thus uniform and homogeneous cooling of water-hardenable steels.

Basin dimensions each 9500 x 3500 x 3000 mm ( L x W x H )